Electropolishing

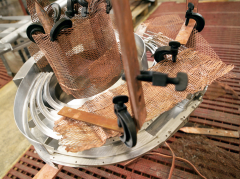

Electrochemical polishing or deburring condenses and smoothes chrome (stainless) steel surfaces of components and improves the look and properties of the surface for use.

The electrochemical method with special electrolyte (medium) and direct current applied abrades metal from the surface of the anodically connected workpiece - without changing the microscopic metallic structure, down to a treatment intensity of 50 µm. The surface is smoothed, rounded and polished.

Pretreatment - electropolishing - aftertreatment …

During the pretreatment, the treated workpiece is degreased. Then the workpiece is electrochemically polished by means of an electrolyte and applying direct current in an electropolishing bath. After the treatment the workpiece is passivated, rinsed, dried, cleaned, controlled and packed.

Size of the bath for electropolishing and pickling: 6000 x 1400 x 1500 mm