Passivation

As well as iron, stainless steel alloys also contain chromium, nitrogen, molybdenum and other components depending on the smelting product. Chromium in particular combines with oxygen to build up a stable layer that is rich in chromium oxide, protecting the system against rouge. This passive layer (as it is known) can be additionally reinforced by chemical passivation. To allow rouge as little opportunity as possible right from the outset, it follows that new systems should be professionally passivated as soon as they have been installed.

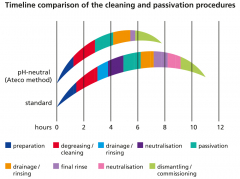

pH-neutral pre-cleaning – passivation – flushing ...

That\'s how the passivation procedure runs. The entire system is flushed through in a closed circuit. To do this, we use chemicals that will not attack the stainless steel pipes. During passivation, a protective layer that is rich in chromium oxide is formed on the surface. The use of suitable chemicals also increases the ratio of chromium to iron on the surface. This is a good thing, because the higher the percentage of chromium on the surface, the more the passive layer will develop - which in turn reduces susceptibility to corrosion.

Regular cleaning and repassivation …

High temperatures (during welding jobs, for example), scratches on the surface or just the passage of time will weaken the passive layer. The effect: rouge can start.